- Home

- About CTI

- Our Services

- Investor Relations

- CTI Mall

- Resource Center

- Reports Validation

- Join Us

-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in CTI’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. CTI is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

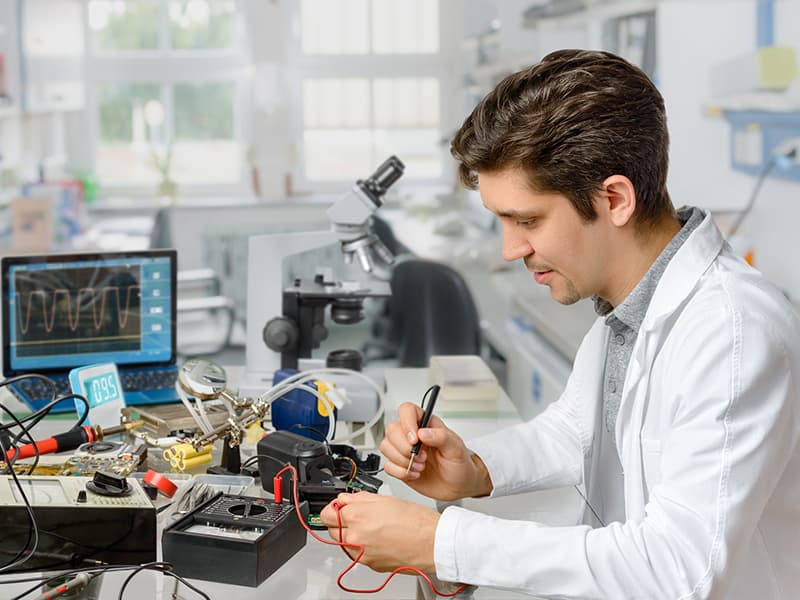

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

- Resource Center

- Application Forms

- Bulletin

- Training Center

- CTI Academy

- Reports Validation

QUALITY & VALUE

-

Input Power TestingMore

Input Power TestingMoreRated Input Power: The input power specified by the appliances' manufacturer. The input power test is one of the common safety performance tests of electronic and electrical products as it is used to evaluate whether the labels are accurate and whether there are dangers of over temperature when the product is used for long periods of time; this prevents the risk of fires from heat released by products during operation.

-

Residual Voltage TestingMore

Residual Voltage TestingMoreThe residual voltage is the voltage between the poles of the power plug and the energy inside energy storing components inside electrical equipment that remains for a period of time after electrical equipment are powered off. The residual voltage test is one of the important safety performance tests of electronic and electrical products as it is directly related to the personal safety of normal users during operation. This is especially true in regard to the safety of household appliances, which can affect the lives and property of thousands of households.

-

Ground Resistance TestingMore

Ground Resistance TestingMoreThe connection resistance between the accessible metal parts of the electrical appliance and the grounding terminal or grounding contact. The ground resistance test is one of the important safety performance tests of electronic and electrical products, used to quantitatively evaluate the grounding continuity of electrical appliances, with the resistance value indicating the reliability of the grounding capability. A grounding resistance that is too large may still cause harm to the human body, otherwise, it functions as protection.

-

Pressure TestingMore

Pressure TestingMoreDielectric Withstand Voltage Test: A test to determine whether the insulation material and the spacing meets compliance requirements by applying a voltage higher than a device's rated value for a period of time. The dielectric withstand voltage test is one of the important safety performance tests of electronic and electrical products, used to evaluate the quality and electrical safety characteristics of the equipment.

-

Current Leakage TestingMore

Current Leakage TestingMoreLeakage Current: The electric current formed, under no external pressure or equipment malfunction, by the surrounding dielectric between insulated electrical parts, ground parts and metals. The leakage current test is one of the important safety performance tests of electronic and electrical products, used to evaluate the safety characteristics the equipment. The existence of leakage current deprives the safety performance of electronic products and pose as potential safety hazards for users.

-

Stability TestingMore

Stability TestingMoreStability: Under normal usage conditions, the instability caused by the equipment's components and structure must not reach levels that will put users or maintenance personnel in danger. The stability test is one of the common safety performance tests of electronic and electrical products, used to evaluate the dangers of an electrical machinery; if stability is not in compliance, harm to the human body may be caused.

-

Mechanical Strength Testing of ShellsMore

Mechanical Strength Testing of ShellsMoreEquipment should possess enough mechanical strength and their structure should guarantee no danger will come when subject to expected operations. The shell mechanical strength test is one of the common safety performance tests of electronic and electrical products, used to evaluate the dangers of the electrical machinery; if the shell mechanical strength is not of compliance, it may cause mechanical and electric shock injuries to the human body.

-

Temperature Rise TestingMore

Temperature Rise TestingMoreDuring normal operation, the temperature of the devices’ components cannot be too high. Some components experience heating from high levels of current, resulting in their temperatures to rise too high. And working under these conditions for long periods of time may reduce the performance of the insulating material, which in turn cause the equipment to risk being electric shocked, burning or catching fire. The temperature test is one of the important safety performance tests of electronic and electrical products, used to evaluate the quality and electrical safety characteristics the equipment.

- About CTI

- Our Services

- Investor Relations

- CTI Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- CTI Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号