- Home

- About CTI

- Our Services

- Investor Relations

- CTI Mall

- Resource Center

- Reports Validation

- Join Us

-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in CTI’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. CTI is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

- Resource Center

- Application Forms

- Bulletin

- Training Center

- CTI Academy

- Reports Validation

QUALITY & VALUE

-

Rubber Ingredients and Products TestingMore

Rubber Ingredients and Products TestingMoreRubber has a wide range of applications. As a basic material product, they have good performance stability, excellent cost performance, and relatively simple post-processing. They are suitable for production into some special tool products or large-scale accessories, but how to ensure the use of rubber What? What tests do you need to do about rubber? Huace can provide you with professional customized services, including material analysis, physical and mechanical energy, rubber chemical composition testing and other testing items.

-

Plastic Ingredients and Products TestingMore

Plastic Ingredients and Products TestingMoreAs a listed testing organization, CTI has developed into a comprehensive testing service organization integrating weather resistance, failure analysis, and physical and chemical. It can use a series of advanced equipment tests to complete the testing of plastic products in accordance with ISO, ASTM, DIN, GB and other standards. Service, issue an authoritative third-party certification report

-

Paint Coating MaterialsMore

Paint Coating MaterialsMorePainting not only decorative but also have a certain physical and chemical properties. Most of the physical and chemical properties of painting are tested on the coating. CTI can provide enterprises with painting physical and chemical performance test, used to predict the performance of the painting, but also can provide the scheme painting formula rectification scheme, make it more suitable for the performance of the construction process to the painting requirements.

-

Adhesive/ Tape TestingMore

Adhesive/ Tape TestingMoreWith the improvement of production and living standards, the adhesives of ordinary molecular structure are far from satisfying people's applications in production and life. At this time, polymer materials and nanomaterials have become effective ways to improve the properties of various materials. Polymer polymerization Materials and nano-polymers have become important research directions in adhesives. On the road of research, China Test can help enterprises to provide physical and chemical performance testing of adhesives and tapes, and weather resistance testing.

-

Light Aging TestingMore

Light Aging TestingMoreLight aging test refers to the aging caused by various factors when materials are exposed to sunlight during use. Light aging tests can simulate the effects of outdoor ageing for months or even years in a few days or weeks. The laboratory can evaluate the aging resistance of materials by evaluating the color, gloss, chalking, blistering, peeling and other appearance changes or mechanical properties of samples.

-

Ozone Aging TestingMore

Ozone Aging TestingMoreMaterials (mainly vulcanized rubber) exposed to ozone medium for a certain period of time will produce specific aging phenomena, such as: cracking, loss of light, discoloration and other changes on the surface of the material; Therefore, the test samples were exposed to a closed chamber containing constant ozone concentration and constant temperature, and the test samples were tested for aging according to the predetermined time and specific conditions. The ozone aging resistance of the test samples was evaluated by the degree of surface cracking or other changes in performance.

-

Salt Spray and Condensation TestingMore

Salt Spray and Condensation TestingMoreCorrosion is the most important factor causing deterioration of metal materials in outdoor environment. Salt spray and condensation test can simulate the corrosion degree of materials in the corresponding environment. The laboratory can evaluate the corrosion resistance of materials by evaluating the corrosion degree, color, gloss, chacking, blistering, peeling and other changes of samples.

-

Temperature and Humidity Aging TestingMore

Temperature and Humidity Aging TestingMoreTemperature and humidity aging refers to material aging in a specific temperature and humidity. It can simulate high temperature, low temperature, specific temperature and humidity and the environment when temperature and humidity Alternate change or are impacted by temperature. The laboratory can evaluate the aging resistance of materials by evaluating changes in appearance and mechanical properties of samples.

-

Analysis-Themed TestingMore

Analysis-Themed TestingMorePolymer materials are widely used. We will use corresponding materials according to specific needs. The characterization of material performance is an indispensable means. CTI provides comprehensive testing services with the help of professional testing instruments and experienced technical teams.

-

Qualitative and Quantitative Component AnalysisMore

Qualitative and Quantitative Component AnalysisMoreAs a professional component analysis institution in China, CTI can analysis qualitative and quantitative analysis of each component of samples through scientific analysis methods, and realizes the analysis of multi-component complex sample system, which brings a series of benefits for enterprises in the society, such as improving formula, improving technology, mastering core technology, improving product performance and reducing cost and so on.

-

HardnessMore

HardnessMoreHardness test is one of the most important indexes to detect the properties of materials. It is also one of the most rapid and economical test methods. The reason why it has become a common method of mechanical property test is that hardness test can reflect the differences of material in chemical composition, structure and treatment process. It is often used as a means of supervision in all walks of life.

-

Thermal PropertiesMore

Thermal PropertiesMoreThe physical and mechanical properties of plastics are closely related to temperature. When the temperature changes, the stress behavior of plastics changes, showing different physical states, showing the characteristics of phased mechanical properties. The physical state and mechanical properties of plastics when heated are of great significance to the molding process of plastics.

-

Mechanical PropertiesMore

Mechanical PropertiesMoreCTI provides raw materials and petrochemical-related mechanical properties services. Mechanical properties refer to tensile strength, impact strength, flexural strength, and tensile elastic modulus, flexural modulus, elongation at break, shear strength, compressive strength, etc. To the performance of resisting external forces.

-

Films and SheetsMore

Films and SheetsMoreComprehensive coverage of plastic films, packaging bags, woven bags and other plastic products, around nearly a hundred subdivision testing items, according to domestic and foreign testing standards, provide authoritative testing reports.

-

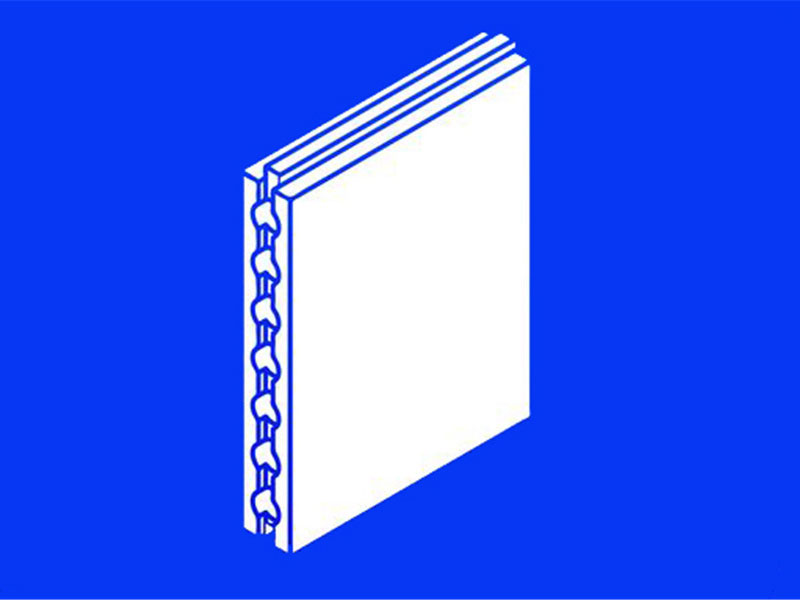

Sandwich ConstructionMore

Sandwich ConstructionMoreGenerally sandwich structure is used for wings, tail, fuselage, speed brake, engine compartment, etc. Compared with thin-walled skins, sandwich panels have a much larger thickness, strong resistance to instability, smooth surface, and good aerodynamic appearance. However, due to the complex manufacturing process and the difficult inspection of process quality, the application is greatly restricted. The materials of the sandwich structure sheet mainly include aluminum alloy, stainless steel, titanium alloy and various composite materials. Interlayer materials include light wood, foam plastic, etc., and metal or composite materials can also be used to make corrugated interlayer or honeycomb interlayer. The interlayer and the surface board are generally glued together, or they can be welded to form a whole.

-

Geotextiles and FabricsMore

Geotextiles and FabricsMoreThe textile fiber test is a basic test for textile products. According to the test requirements, the sample is tested in a wet or dry state, and the sample is taken from the fabric in the radial and weft directions of the fabric.

-

Foaming MaterialsMore

Foaming MaterialsMoreFor foaming material testing, we provide you with a full set of test programs, including polymer foaming material testing, inorganic foaming material testing, etc., for all aspects of the physical and chemical properties of foaming materials, to verify whether the foaming material is in a specific use environment Meet your requirements and provide professional test reports.

-

Rubber TracksMore

Rubber TracksMoreTesting provides professional rubber track, artificial grass testing and certification services, providing officially recognized testing reports, according to national standards, industry standards, and local standards to provide comprehensive and professional physical performance testing services for plastic runways.

-

Composite MaterialsMore

Composite MaterialsMoreThrough failure analysis, find the possible causes of product failure in the design, production, process, storage, and transportation stages, and in-depth study of product failure mechanism, providing theoretical basis for improving product yield and optimizing production process.

-

Natural LatexMore

Natural LatexMoreNow more and more people pursuit of quality life, and The latex pillow in Thailand is popular in recent years, it is become a characteristic products when you have a trip to Thailand, while we must be careful because there are a lot of pits in it. Latex pillows bought from outside or e-commerce are not real natural latex pillows in many cases, it was made of synthetic rubber. CTI experts tell us that synthetic rubber may contain styrene which is a suspected carcinogen.

-

Polymer Failure AnalysisMore

Polymer Failure AnalysisMoreFailure analysis has strong practical significance in improving product quality, technology development, improvement, product repair and arbitration of failure accidents. CTI is a third-party laboratory focusing on failure analysis technology services. it has established a good reputation in the industry due to the service in the field of failure analysis with many years.Its independent third-party status, a large number of accumulated cases and databases enable us to provide customers with fair, independent and accurate failure analysis reports.

- About CTI

- Our Services

- Investor Relations

- CTI Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- CTI Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号